Shenzhen Jianke Electronics Co., Ltd

Shenzhen Jianke Electronics Co., LtdSince the beginning of the establishment, Jianke electronics has held the business objective to provide zero-defect products to customers for more than ten years, which has gradually set up the enterprise business card in the industry.

Quality is the life for automobile electronics. Jianke strictly adheres to the specifications of the IATF16949 quality management system and IPC III level requirement and establishes various effective quality control procedures, such as product’s advanced quality management APQP, PPAP control, production process management, product identification, tracing management, change management and so on.

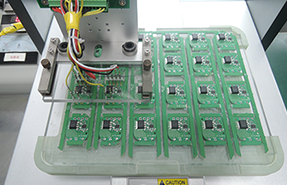

For electronic components, Jianke has cooperated with international semiconductor directly, per other key parts such as PCB are from well-known domestic auto industry identified suppliers and carry out strict IQC to ensure the reliability on the materials. The whole process IPQC, including SPI, AOI, ICT, FCT and so on, can guarantee the stability of the product process and restrict the defectives to outflow.

SPI

1. 3D on line solder paste test system; effective resolution 56nm

2. According to the fluctuation of the solder paste height, the thickness variation of the solder paste is calculated and the thickness distribution is depicted, so that the solder printing quality can be monitored and reduce NG.

AOI

1. 3D on line automatic optical inspection; effective resolution 16.1 um

2. As the tool for reducing defects, find and eliminate the error during SMT to realize good process control.

ICT

1. Soldering defects detectable: short circuit, false soldering, fake soldering, disconnection

2. Component defects detectable: missing parts, direction, incorrect material, stand off height, component defect.

Quality engineer and process engineers continuously optimize the production process through QC improvement activity and 6 sigma project; irregular quality training, on-the-job training OJT and OPL enhanced quality consciousness of the whole staff, so that the proposal improvement activity can attract all staff to join in the quality improvement. Day by day, Jianke has accumulated rich experience in the production process of PCB, the common industry challenges such as false welding and void content can be controlled effectively.

It is the Niyamas that can realize the enterprise’s objetive to provide zero-defect products to customers. Customer’s praise is also our motivation of no arrogant and rash, and continuous improvement.