Shenzhen Jianke Electronics Co., Ltd

Shenzhen Jianke Electronics Co., Ltd

In the background of the growing tide of industry 4.0, intelligent manufacturing and internet +, if the manufacturing industry intends to speed up the pace to smart factory, in addition to upgrading existing production automation level, it needs more intelligent and open information systems to face increasing requirements for production, quality and personalized product needs. Throughout the production process, there are many software systems to ensure the smooth operation of the company.

ERP

Jianke uses ERP to manage the enterprise. This enables the the on-site production order and data can be delivered and collected by form, which lets the actions become data and pass information through the system during the process. On one hand, it can trace the information per bill, on the other hand, it can prevent human error. All in all, ERP can provide real-time information across departments and set up the data procedure of Jianke’s daily work.

PLM

PLM applies to the internal enterprise located in a single site or the enterprises which cooperate with each other in the product R&D section, and it provides solution for the establishment, management, distribution and application of product’s life cycle. Jianke integrates human resources with product by PLM system. After its application, Jianke can keep track of the information of the whole product cycle and update it so as to improve the communication speed and speed up the product development to enhance the developing efficiency.

MES

MES is a set of production information management system for the workshop of manufacturing enterprises so as to build a solid, reliable, comprehensive and feasible manufacturing collaboration management platform. According to the implementation of MES, Jianke can monitor the production event and guide and deal with the production per current data. The quick response to the state change can lead to widely application in industrial production for Jianke. MES can reduce the non-value activities interally and guide factory to work efficiently, thus the lead time can be shorted and the logistics of materials can be effective which can improve the production rate of return.

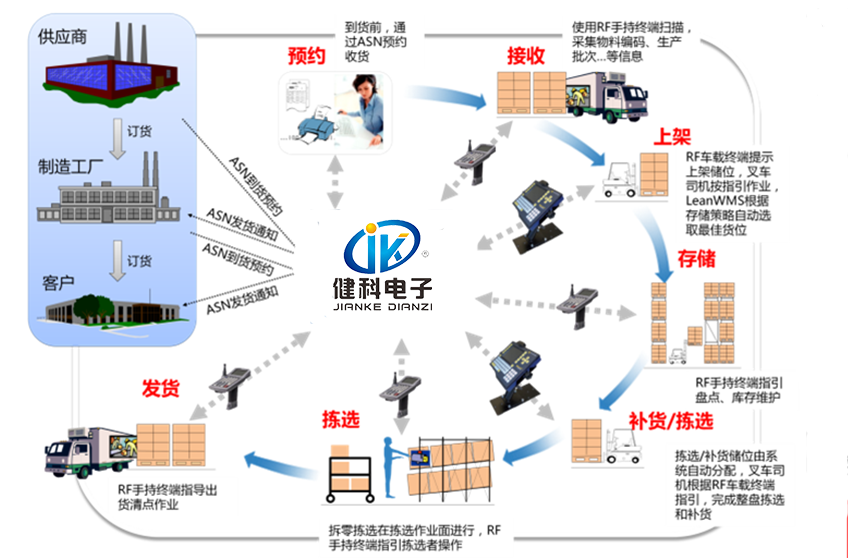

WMS

The application of warehouse management system and automatic vertical carousel upgrades the intelligent storage level:

1. Timely data, precise procedure, fully auto-oriented, high-efficiency.

2. Accurate position management and fully use of the storage space

3. The upper and lower racks of goods are organized by the system to avoid human errors and ensure FIFO.

4. Inventory control updates just in time

5. Automatic collect information of batch management to realize the traceability of product’s production and sales.

Furthermore, the bar code management can initiate company to be managed from relaying on experience traditionally to relay on accurate data analysis, which can accelerate supply chain responsiveness and enhance company’s overall competitiveness.