Shenzhen Jianke Electronics Co., Ltd

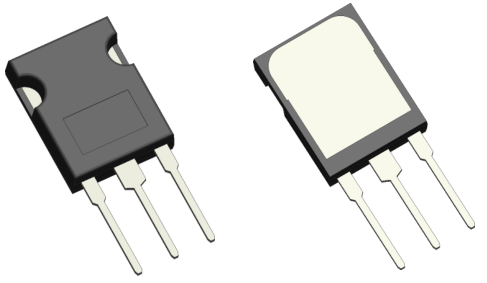

Shenzhen Jianke Electronics Co., LtdSaid “plastic packaging” is a technology that packages the ignition module with an insulating epoxy material. For example, the actual volume and appearance of IM-A00740A-45 are not the same size and appearance of the actual control circuit but the size and appearance that the drive IC and triode have been packaged.

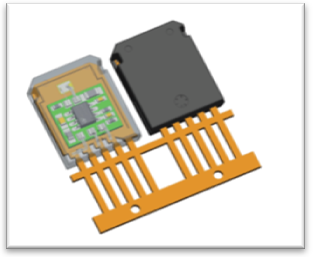

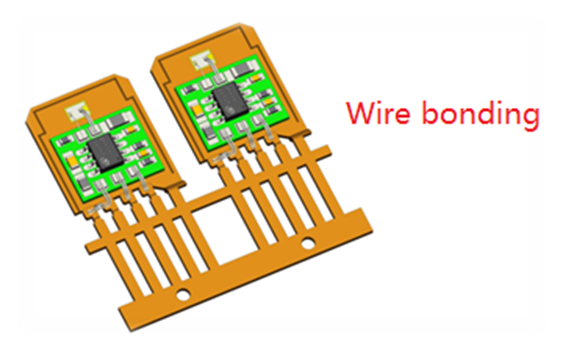

Plastic packaging is the shell of the ignition module, which not only plays the role in sealing and enhancing thermal conductivity, but also as the bridge that connects the inside parts with the outside circuits. Jianke applies DIE BONDING to paste WAFER to designed metal frame, and do the wire bonding with aluminum or gold wire by different wire size per products, and using ultra energy to achieve the connection of WAFER and WIRE FRAME. Therefore, plastic packaging is vital to produce ignition module.

According to the packaging design, there are eight types, which can be classified as active modules and passive modules.

Jianke’s modules are made up of different integrated circuit and drive IC accordingly. In terms of such kind of products which mainly contain drive circuits, the plastic packaging technology not only guarantee the isolation between the internal circuit with the external to prevent the pollution from impurities in the air to cause poor electrical properties, but also has an advantage of outstanding insulation and anti-static properties. What’s more, this packaging technology is keeping on upgrading. Jianke’s plastic packaging modules become smaller, more dedicated, for example, the G series developed from C series. Besides the G series’ small size, the G series has made great progress in the application and electrical features, which is benefit from the new packaging technology and independent developed ASIC.

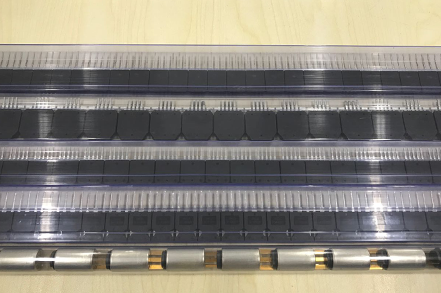

After the semi-finished process, the products have to go through rest processes of molding, post mold cure, trim, form, label, test and package, and finally deliver to customers.